Product Development

Less waste, just water

Key Achievements

"Without you, we wouldn't be where we are, guys!"

Rastislav Rusňák, Executive Representative at WTR

Client

WTR is a forward-thinking company specializing in water treatment systems and sustainable water management. It provides innovative, cost-effective, and automated end-to-end wastewater treatment solutions.

Case study

The need

WTR was looking for a partner to develop a comprehensive solution (software, system architecture, and development, while integrating seamlessly with the required hardware) that would enable customizable control for their wastewater treatment systems, which all have individual requirements depending on their locations.

The goal was to develop custom solutions that redefine wastewater treatment, making it smarter, more efficient, and sustainable. To achieve this, WTR needed a fearless partner, ready to tackle and resolve all the complex and challenging specifics the project was likely to bring.

Our solution

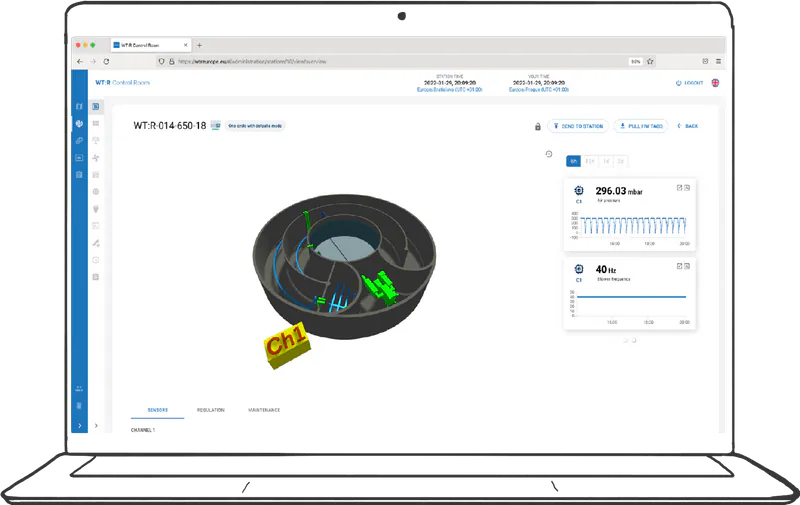

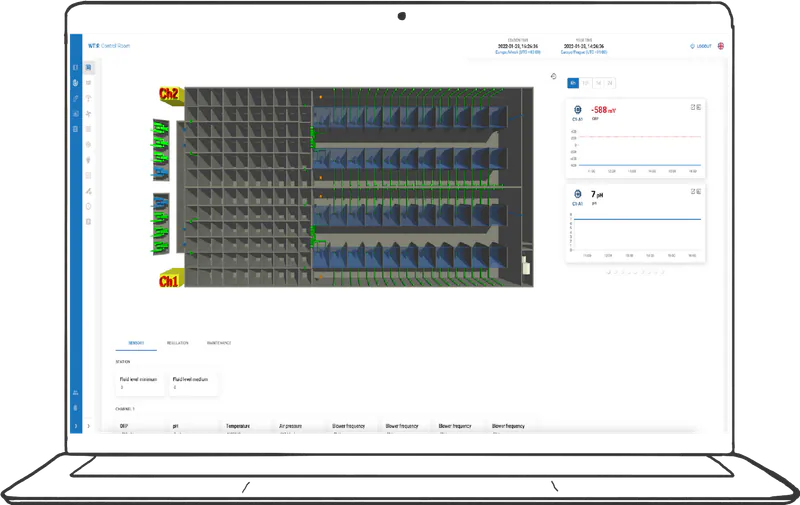

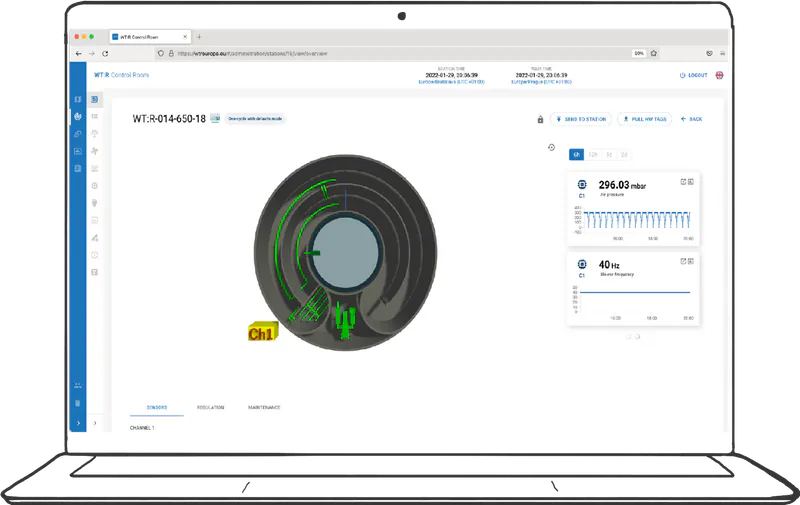

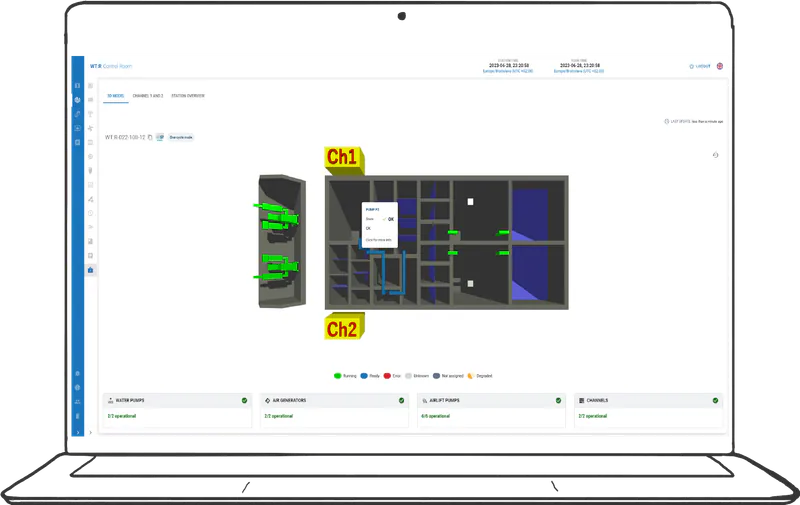

We developed a unique greenfield solution of software components, which included hardware modules connected to the worldwide Central Control Room, that are secured by Hardware Security Modules. The software is highly customizable. The structure of each solution can be defined and customized according to the individual needs of a specific place. The system is currently implemented in China and several other European countries.

Key results

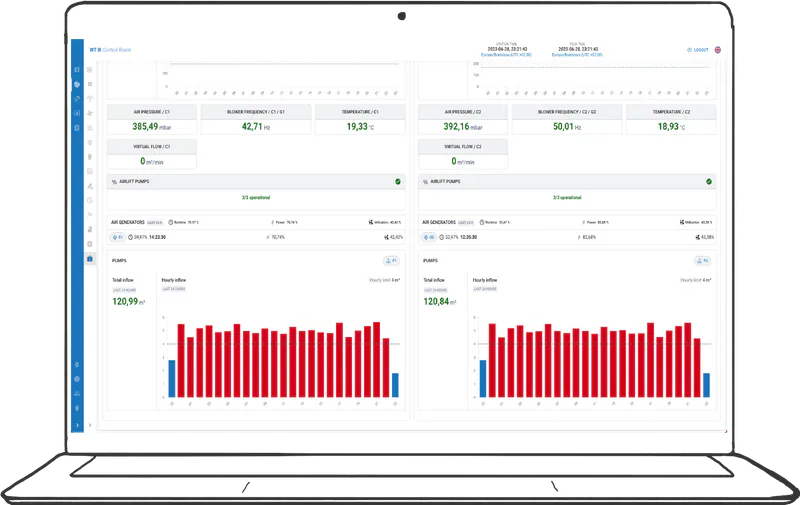

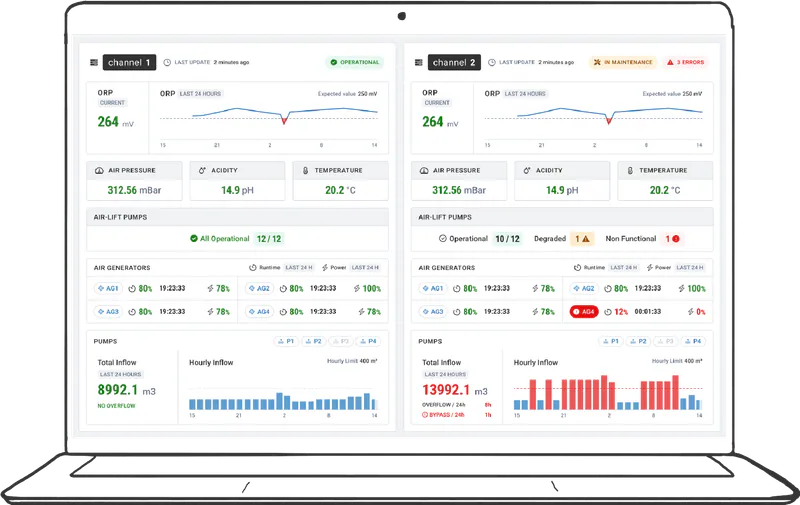

- Real-time monitoring and control of Waste Water Treatment Systems (WWTS), from small-scale (100m³) to large-scale (100,000m³ and beyond), with no size limitations.

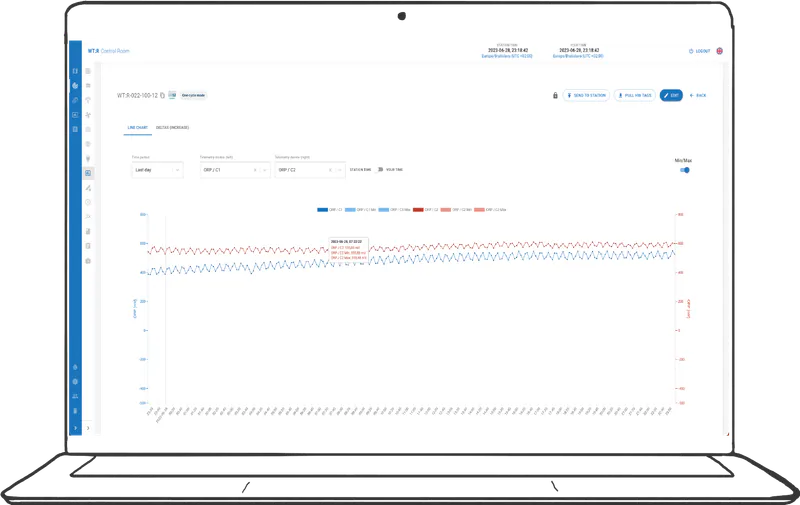

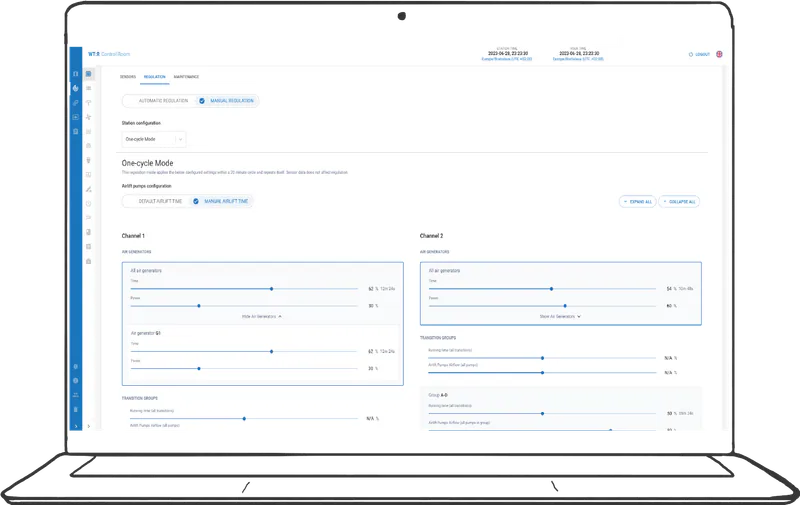

- Hundreds of elements are driven by artificial intelligence based on the Fuzzy models. Manually defined operation modes with fine-grained scheduling are also possible.

- Modbus TCP API enables seamless integration with existing industrial infrastructure, providing both sensor data access and third-party connectivity for monitoring, automation, and control. By exposing Modbus for external systems, we ensure compatibility with SCADA/PLC environments while enabling modern Industrial Internet of Things (IIoT), cloud-based analytics, and predictive maintenance solutions.

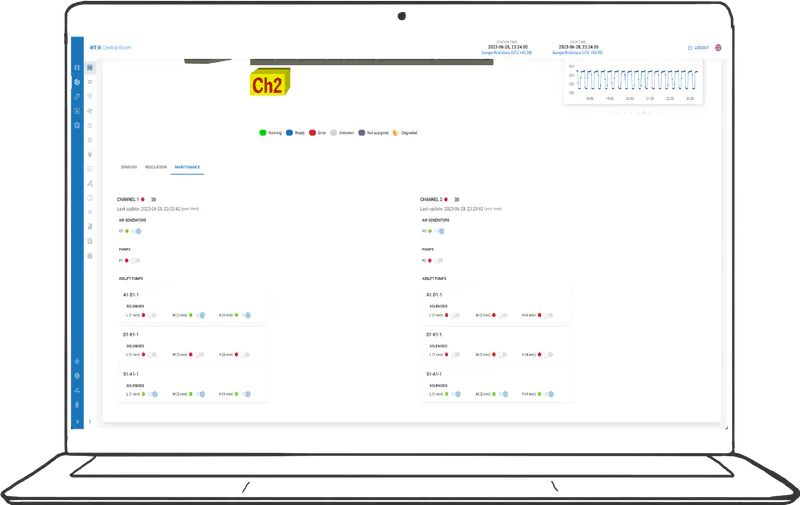

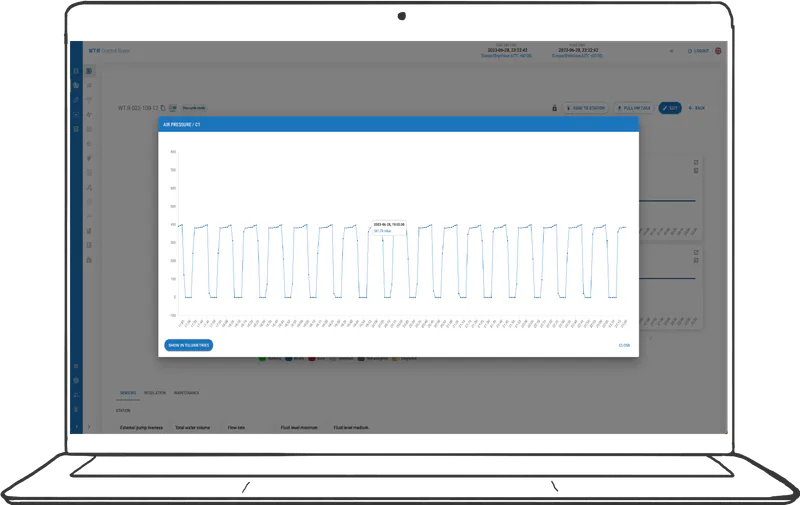

- Extensive dashboards with operational details.

- Real-time telemetry streaming enables visualization of real 3D models in both the Local and Central Control Room.

- Each WWTS (Wastewater Treatment System) is equipped with a dedicated Hardware Security Module (HSM) that acts as a unique digital fingerprint, enabling secure, humanless authentication for network connectivity.

- New state-of-the-art interface built on top of the React and Material user interfaces.

- This solution played a pivotal role in a containerized wastewater treatment plant — the first of its kind in Slovakia.

- Successful and ongoing collaboration since 2019. Our collaboration has evolved into a full-fledged partnership. Find more: https://www.wtr.global/

- Complex project delivery, including the architecture for seamless hardware integration—leveraging industrial protocols, PLCs, and IIoT connectivity.

- The project continues to evolve further by adding new locations, which each have their own specific needs.

- https://www.hotovo.com/case-study/wtr

Tech stack

This complex project required a diverse set of technologies to meet various prerequisites and system constraints rather than a lack of direction in technology selection. Each tool was carefully chosen to fulfill a specific requirement, ensuring seamless integration between hardware, software, and automation processes.

Below is a breakdown of the key technologies and their roles:

- Frontend: React + Redux, Material UI, Webpack (UI components & performance optimization), Leaflet (mapping), ChartJS (data visualization), Electron (cross-platform desktop applications)

- Backend: Quarkus (Microprofile - Java EE), Hibernate, PostgreSQL + TimescaleDB (time-series data management), RabbitMQ & MQTT (messaging protocols for real-time communication), Gradle, MapStruct, RestEasy, jFuzzyLogic (fuzzy logic processing for automation).

- IoT & Edge Computing: C++, OPC (Open62541 for industrial automation), Simatic, Pistache (lightweight HTTP server), ZMQ (high-speed messaging), HSM (Yubikey for hardware security).

- Hardware Integration: Revolution Pi, Simatic, LOGO! – essential for industrial automation and control.

- Automated Deployment & DevOps: Kubernetes, Flux (GitOps for automated updates), Docker, Terraform (infrastructure as code), Aptly (package repository), Nginx, LXC containers, Bitbucket CI (Pipelines), Ansible (specifically used for firmware generation and deployment).

Team size

- Technical Solution Architects

- Back-End Developers

- Front-End Developers

- UI/UX Designers

- Project Manager